Onderzoek naar de kwaliteit van Nederlandse lavendelolie

door Henk Ploeger, senior destillateur INDEKOPERENKETEL

Inleiding

Begin 2012 vroeg ik mij af wat het verschil is tussen lavendelolie afkomstig van planten die in Nederland groeien en bijvoorbeeld in Frankrijk. Is de olie minder, anders of heeft het z´n eigen specifieke eigenschappen? Om dat uit te zoeken heb ik in 2012 en 2013 met hulp van enthousiaste vrijwilligers in Ulvenhout en Chaam groeiende lavendel geplukt. Om er daarna via stoomdestillatie lavendelolie uit te halen.

Hiervoor had ik wel grote hoeveelheden lavendel nodig. Dat was mogelijk door het contact wat ik had met een lavendelkwekerij in de buurt, waar ik in 2011 al een bescheiden hoeveelheid lavendel had geplukt en gedestilleerd.

Lavendeloogst

Ik heb op basis van de hoeveelheid geur die de diverse lavandelsoorten op de kwekerij afgaven Lavandula angustifolia var. little Lady uitgekozen voor dit project. Het gaat om een cultivar die in plm 3 jaar tijd van klein plantje opgekweekt wordt tot een grote potplant. Tijdens dat kweken moeten de planten ook regelmatig gemaaid worden.

In de bedrijfsvoering van de kwekerij blijft na het mechanisch maaien het maaisel op de grond liggen. Deze waardevolle grondstof kon ik dus met hulp van vrijwilligers zelf gaan oogsten.

De oogsten vonden plaats eind juni, begin juli, in de bloeitijd van de lavendelplanten. Deze pluktijd is afhankelijk van het weer.

We hebben in zowel 2012 als 2013 een hoeveelheid van 100 kg lavendel geoogst. Dit gebeurde verspreid over twee middagen, en had te maken met de droogcapaciteit waar ik over kon beschikken. Het aantal vrijwilligers en hun enthousiasme was geweldig, we hebben zelfs een aantal mensen moeten teleurstellen omdat we toestemming hadden om met maximaal 8 mensen aan de slag te gaan.

De toeloop van vrijwilligers werd in 2012 ook voor een deel veroorzaakt door een leuk stukje in BNdestem over deze activiteit. In ruil voor voor het meewerken hebben de vrijwilligers een workshop Lavendel destilleren aangeboden gekregen.

Mijn verwachting was dat 100 kg bloeiende lavendeltoppen voldoende zouden moeten zijn om ongeveer 1 liter lavendelolie van te destilleren.

Drogen en destilleren

Voor het drogen van deze hoeveelheid lavendel heb ik gaasbakken gebruik die makkelijk te stapelen zijn. Ik had capaciteit voor ongeveer 50 kg. Het drogen van de lavendel voor het te destilleren is geen noodzaak, maar had meer te maken mijn de inhoud van de destilleerketel.

Per destillatie kon ik vier volle klapkratten (komt overeen met 16 kg plukgewicht) lavendel in de destilleerketel kwijt.

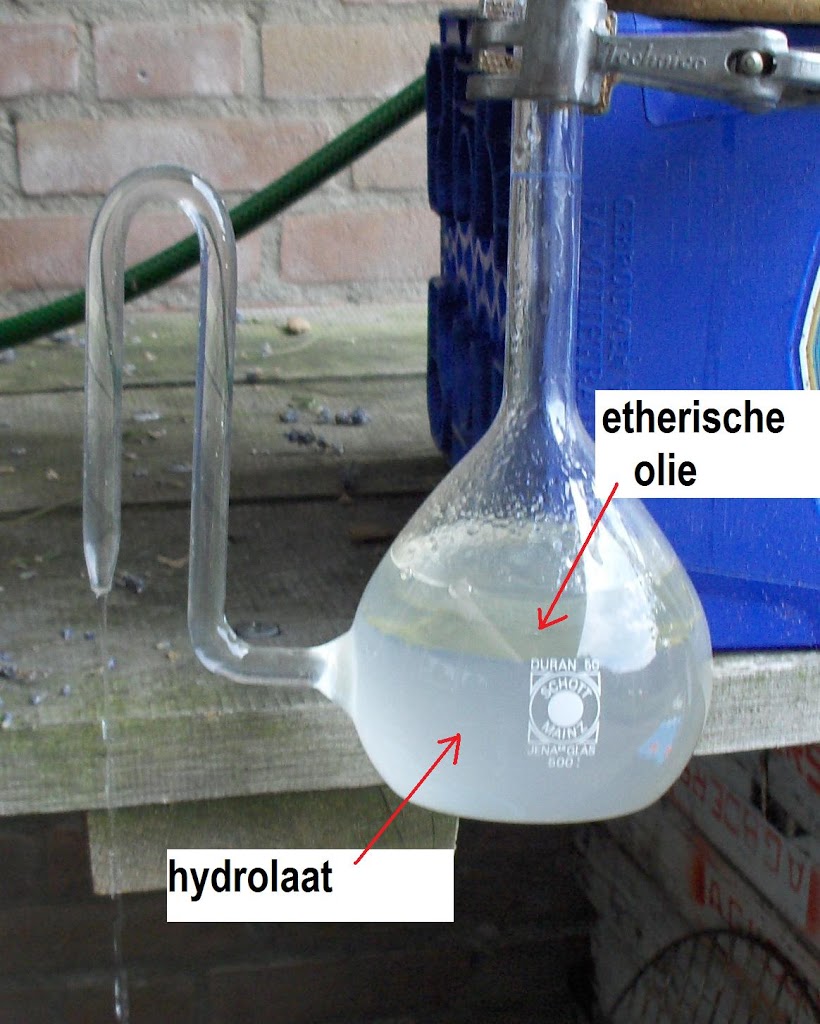

Tijdens de destillatie heb ik gebruik gemaakt van een ´florentijnse vaas´om hydrolaat en olie continue te kunnen scheiden.

De olie is in het begin van de destillatie bijna kleurloos, maar veranderd naar een meer gele kleur. Ook de geur van de olie is tijdens de destillatie merkbaar aan het veranderen.

De eerste destillatie van de geoogste lavendel in 2012 duurde ongeveer 2,5 uur en leverde 140 mL olie en 7 liter hydrolaat op. Dus de 16 kg lavendel had een opbrengst van 0,88%. Na het destilleren van de hele oogst in 2012 had ik een opbrengst van 0,8%, wat overeenkwam met in totaal 800 mL lavendelolie.

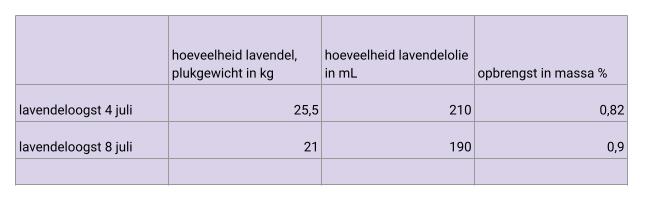

In 2013 kon ik uit dezelfde hoeveelheid (100 kg) bloeiende lavendeltoppen ruim 1 Liter lavendelolie destilleren. Dat was dus een opbrengst van ruim 1%. Dit had alles te maken met het weer en de perfecte plukcondities die we hadden. De hoeveelheid zonlicht die de planten ontvangen in de dagen voor de oogst is namelijk van invloed op de olieproductie. Om dat te testen heb ik in 2013 een deel de oogst van 4 juli en 8 juli apart gedestilleerd. De oogst op 4 juli was voorafgegaan door een aantal regenachtige en koudere zomerdagen. In het weekend erna werd het warm en zonnig zomerweer. Prima condities dus voor de oogst van 8 juli. Resultaten in onderstaande tabel laten overduidelijk zien dat de opbrengst van de oogst op 8 juli bijna 10% hoger lag.

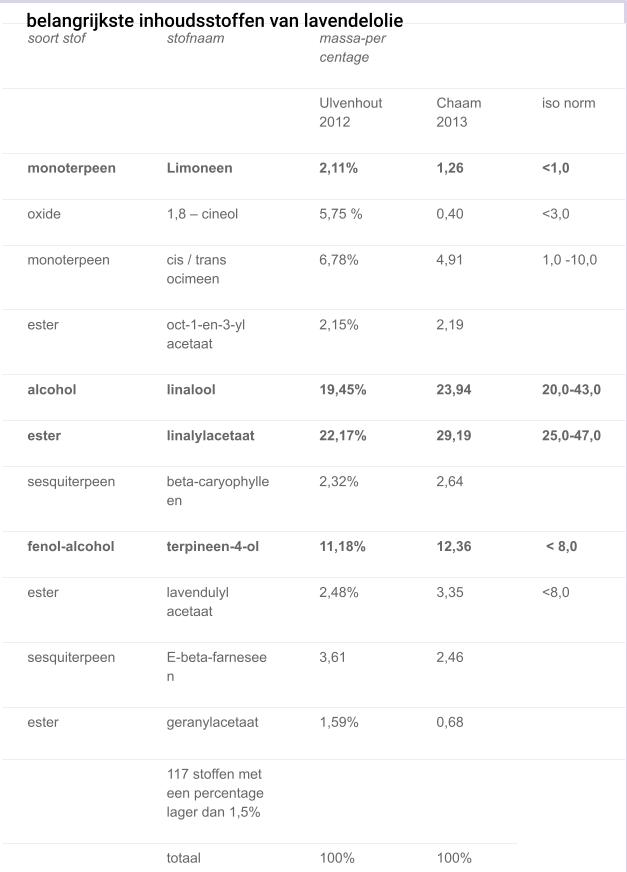

Naast de kwantiteit van de geproduceerde lavendelolie was ik vooral geïnteresseerd in de kwaliteit. Om dit te laten onderzoeken heb ik een bedrijf in Frankrijk gevonden die de samenstelling van de olie en de aanwezigheid van bestrijdingsmiddelen heeft geanalyseerd. De resultaten van de analyse naar de samenstelling heb ik voor de belangrijkste stoffen hiernaast in een tabel weergegeven.

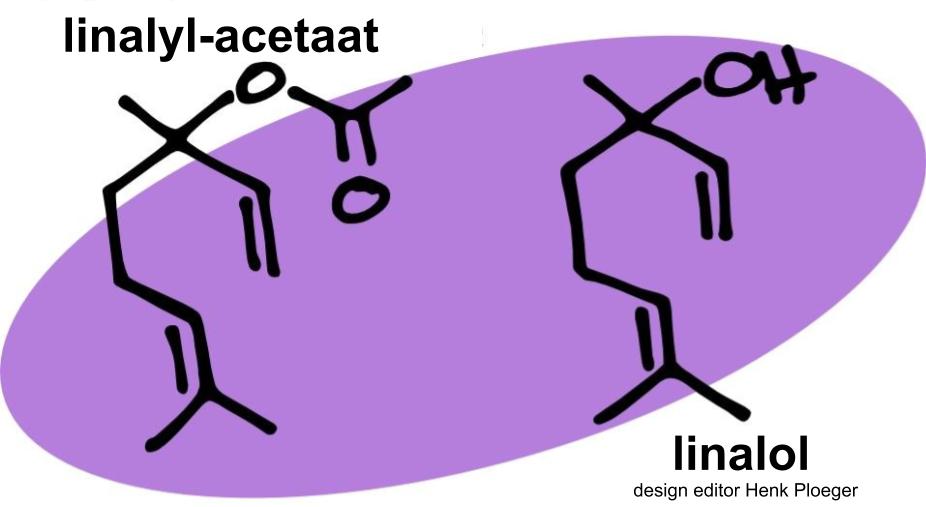

Wat opvalt is dat de etherische olie die ik in 2013 heb geproduceerd wat betreft de hoeveelheid linalol en linalylacetaat voldoet aan de iso-norm. Daarnaast werd in de olie van 2012 zowel als 2013 een hoog percentage terpineen-4-ol gevonden.

Wat vertellen deze analyses over de kwaliteit van de Nederlandse lavendelolie? Omdat de samenstelling anders is vergeleken met een Franse lavendelolie van Lavandula angustifolia zal de olie ook anders ruiken.

De analyse laat zien dat de Nederlandse olie een uniek karakter heeft en zegt ook iets over de therapeutische waarde van de olie. Ik heb dan ook Madeleine Kerkhof-Knapp Hayes van De levensboom gevraagd naar de totale samenstelling te kijken.

Het is belangrijk om daarin ook stoffen die in relatief lage concentraties aanwezig zijn te betrekken omdat ze van therapeutische waarde kunnen zijn.

Dit was de conclusie van Madeleine over de lavendelolie die ik in 2012 had geproduceerd:

Inderdaad is linalool en linalylacetaat wat magertjes maar door de grotere hoeveelheid terpinen-4-ol heeft het wel een behoorlijke fungicide activiteit. Vlak ook de sterk zuiverende invloed van ocimeen niet uit. Een goede olie voor in zeep dus inderdaad, maar ik denk dat er ook een kalmerende invloed vanuit gaat. Zit ook best aardig wat myrceen in. Ik zou deze inzetten voor wonden en huidinfecties, acne, pijnen.

Dat was geweldig nieuws. In 2013 voldeed de olie wat betreft het linalol en linalylacetaat gehalte wel aan de normen, en hadden we een lavendelolie gemaakt die nog breder inzetbaar was door de schimmelwerende werking ervan. Een superolie dus voor aromatherapeuten.

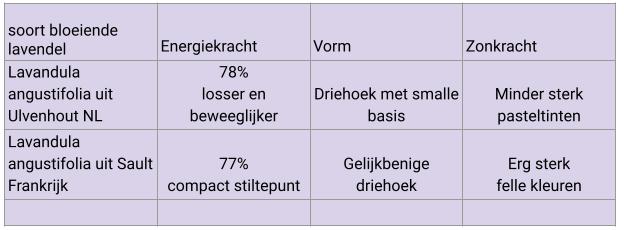

De lavendelolie van 2012 is ook energetisch getest door Josephine Siebers die jarenlang etherische olieën heeft getest voor het merk Chi. Zij heeft de Ulvenhoutse lavendel vergeleken met een biologische olie van ook Lavandula angustifolia uit Sault. Hieronder zie je haar bevindingen. De conclusie van Josephine: “Je mag de distilleerder feliciteren met zijn mooie resultaat. Het is een lavendelolie van hoogwaardige kwaliteit. ”

Van een deel van de olie die ik in 2012 geproduceerd had heb ik zeep laten maken. Werfzeep werkt met gecertificeerde biologische oliën om de zeep te maken. Voor de lavendelzeep is olijfolie, kokosolie en cacaoboter gebruikt. Deze oliën zijn verzeept met loog. Na de verzeping is de lavendelolie en kleurstof toegevoegd. Als kleurstof is een extract van de wortel van ossetong, ook wel alkanetextract genoemd, gebruikt. Deze rode kleurstof veranderd tijdens het verzepingsproces in een mooie lavendelpaarse kleur.

Pesticiden analyse

Naast de samenstelling van de olie was ik ook benieuwd of er eventueel pesticiden in de lavendelolie zouden zitten. In 2012 met de oogst in Ulvenhout was dat niet het geval, maar van de lavendeloogst van 2013 in Chaam bleek de olie hele lage concentraties hexachlorobenzeen (fungicide) en pentachloroanisole te bevatten. De waarden lagen net tegen de detectiegrens van 0,01 mg/kg olie. Dat was natuurlijk jammer, vooral omdat er in 2012 geen pesticiden waren aangetoond in de olie. De concentratie van de genoemde pesticiden lag 3000 maal onder de strengste meest recente norm. Ik heb aromatherapeute Madeleine Kerkhof-Knapp Hayes van De levensboom om advies gevraagd over het mogelijke gebruik van de olie. Zij adviseert om de olie niet op de huid te gebruiken en of direct te inhaleren, maar verdampen in een ruimte kan wel heel goed. Ondanks dat de olie aan strengste normen voldeed heb ik in 2013 besloten om de olie niet te gaan verkopen omdat ik mijn klanten een natuurzuiver lokaal product wil kunnen aanbieden.

Naar de herkomst van de twee bestrijdingsmiddelen is het een beetje gissen. Het kan zijn dat de grond in Chaam bij het telen van verschillende soorten gewassen in de loop der jaren meer verontreinigd is geraakt met de bestrijdingsmiddelen dan de grond in Ulvenhout. Een middel als hexachlorobenzeen zou daar op kunnen wijzen, omdat dit middel al jaren op de lijst van verboden bestrijdingsmiddelen staat. Dit soort middelen die de plant via de bodem opnemen lossen goed op in vetachtige stoffen, daardoor komen ze uiteindelijk sterk geconcentreerd in de etherische olie terecht.

Conclusie van het lavendelproject

Het lavendelproject heeft mij in ieder geval een hoop informatie opgeleverd over de samenstelling en gebruiksmogelijkheden van etherische olie van in Nederland groeiende lavendelplanten. Voldoende denk ik om mensen te motiveren om lavendel biologisch en op schone grond te gaan telen. De Nederlandse lavendelolie heeft een andere specifieke samenstelling en kan zich meten in kwaliteit met bijvoorbeeld de Franse. Het lavendelproject waar ik samen met Catharina, en de hulp van enthousiaste vrijwilligers, met veel plezier aan heb gewerkt, was zeker de moeite meer dan waard!

Wil je een redelijke hoeveelheid lavendel (vanaf 4 kilo) laten destilleren, neem dan contact op met INDEKOPERENKETEL en mail naar indekoperenketel@gmail.com

Contact

INDEKOPERENKETEL destilleerwerkplaats in Gilze | Henk Ploeger en Catharina de Bruin | indekoperenketel@gmail.com | tel 06-18076977 (Catharina) of 06-34068220 (Henk)

INDEKOPERENKETEL is ingeschreven in het Handelsregister

onder de naam H&C Aromalab.